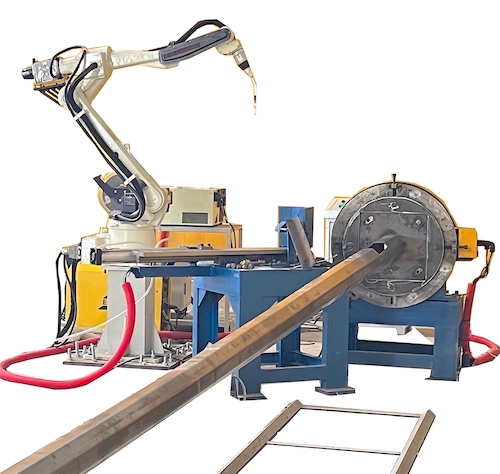

| Light Pole Base plate robot auto welding machine:BW-300/12000 |

|

|

Application and Usage: *Auto weld the base plate and stiffeners to column of pole. *Max welding diameter of the pole:300MM *Max welding length of the pole:12-14Meter *Max welding thickness of base plate:12mm *Max welding sizes of base plate:700x700mm |

Main parts: *Light pole supporting bench *Base plate clamping-rotation device *KAWASAKI welding robot *ESAB welding power source *Stiffener auto feeding system |

|

KAWASAKI ROBOT:BA006L |

|

|

E10 CONTROL CABINET FOR KAWASAKI ROBOT

5INCH REMOTE TOUCH CONTROL SCREEN |

| ESAB-TRANSMIG 400I WELDING POWER SOURCE |

|

|

AUTO STIFFENERS FEEDING DEVICE,AUTO FEED THE STFFENERS WHEN DO THE WELDING PROCEDURES |

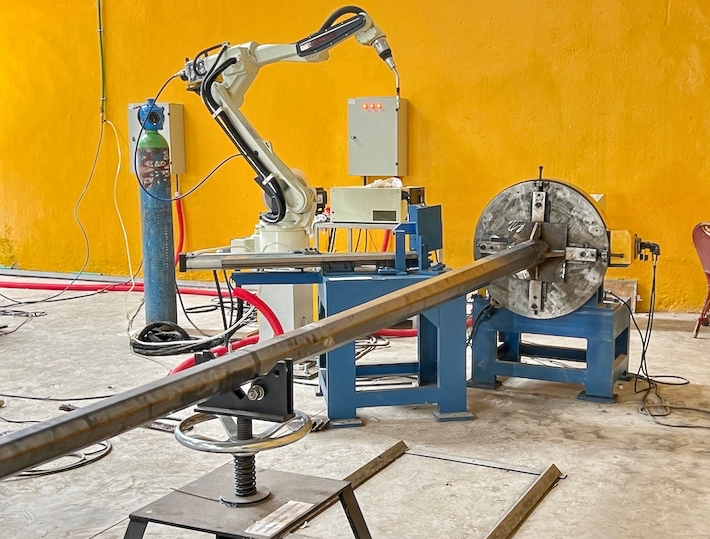

| FINAL WELDING QUALITY |

|

| MAIN PARAMETERS OF POLE BASE PLATE ROBOT AUTO WELDING MACHINE | ||||||||||||||||||||||||||||||||||||||||||

|