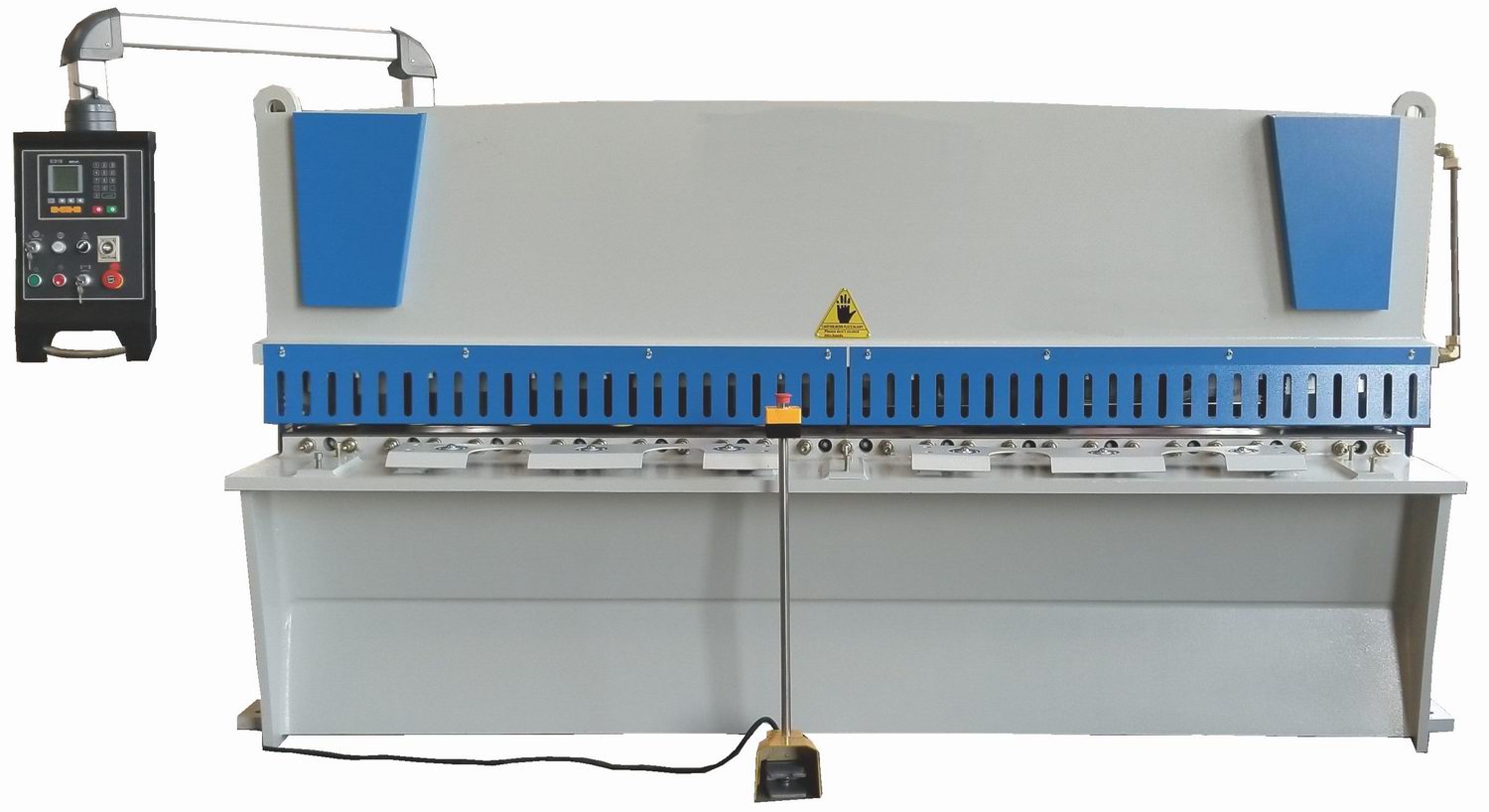

W11 SERIES:3 ROLLERS MECHANIC ROLLING MACHINE:

1. Main Features:

Streamlined designed originated from EU, the use of the overall frame welding and annealing treatment; Three-roller symmetric structure; driven by screw lever and turbine worm, the upper roller moves in vertical direction in the center symmetrical position between the lower two rollers; As the main drive roller for rotary motion, two lower rollers are engaged with the output gear of the reducer to provide torque for rolling plate. The machine is compact, easy operation and maintenance; besides, the roller is suitable for installation of profile dies for easy rolling of various profiles. Easy-to-use removable console. Two sets of digital output for easy positioning of two lower rollers. Induction hardened forged rollers or high strength work rollers with SAE 1050 quality certificate. Upper roller lifting motion principle: auxiliary motor and auxiliary reducer drive the worm and turbine under lateral bearing seats to move, consequently rotate the screw nut on the turbine to lift screw lever. Unloading device: when finishing rolling work, the upper roller rises up, the pull rod on the end of upper roller holding the roller, then disconnects the left bearing seat namely tiltable bearing seat and extracts the pin shaft, turnover the tiltable bearing seat, finally, the finished ferrule will be released from the other end of the upper roller.

2. Standard configuration:

Easy-to-use removable console

The upper roller is electrically depressed through the console

Suitable for thin and heavy plate, aluminum or stainless steel sheet rolling

Ferrules in full circle or varying radiuses can be done easily Overload protection

Two sets of digital output for easy positioning of two lower rollers

Extended roller shafts for profile and pipe rolling operation

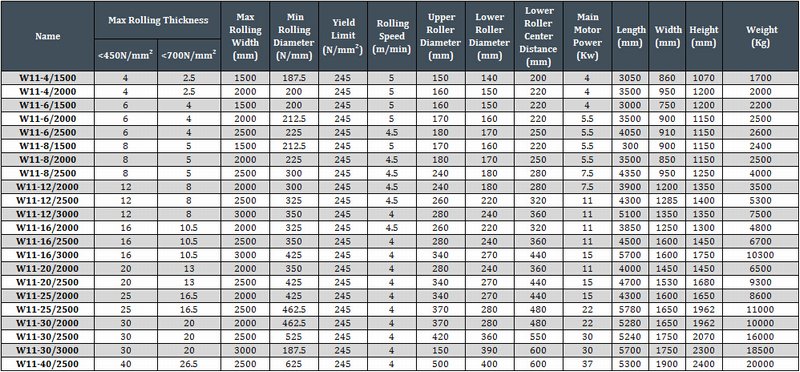

3. Parameters: